Industrial Steel Grating

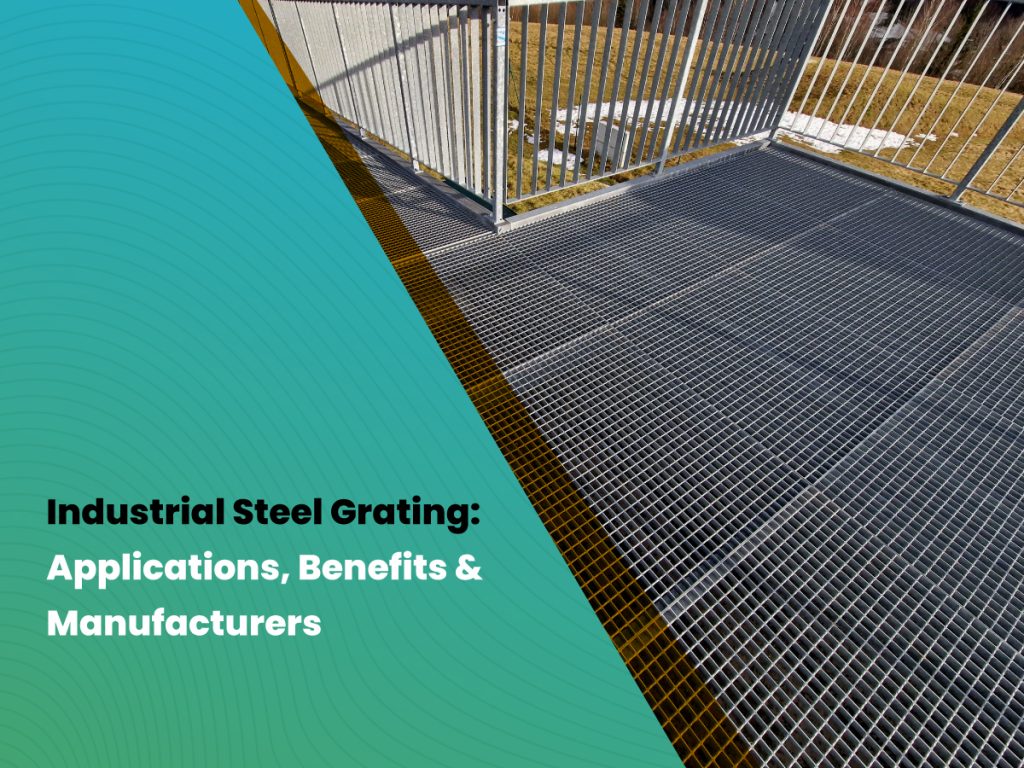

Throughout all Indian Industries (Manufacturing Plants, Power Stations, Refineries, Infrastructure Projects, etc.), Steel Grating Provides High Strength Open Decks and is used to Support Heavy Loads While Making Sure That Safe Passage, Drainage And Ventilation Are Provided To Employees. Steel Grating is made from Mild Or Stainless Steel. Steel Grating Is Perfect For Walkways, Platforms, Stairwells And Trenches and Provides Durability and Low Maintenance. Therefore, It Makes Sense For Industries To Partner With A Grating Supplier That Has Experience And Can Provide Customized Solutions That Meet Industry Standards. For Example, An Industrial Steel Grating Manufacturer (In Gujarat) OR An Steel Grating Manufacturer That’s Trusted In India Will Provide Reliable Performance Over A Long Service Life.

The foundation of India’s industrial infrastructure rests on the strength, durability, and functionality of its floors and access systems. The use of Industrial Steel Grating is key to the success of the majority of industrial sectors, such as Oil Refineries, Manufacturing plants, and more throughout Gujarat, Maharashtra, Tamil Nadu, and many other areas.

This guide is designed to give you an overview of Industrial Steel Grating, including types of grating, applications for the grating, benefits of Steel Grating, and what to look for when selecting your manufacturer of Steel Grating.

What is Industrial Steel Grating?

Industrial Steel Grating is a type of metal construction made from two different types of bar stock. The first type is referred to as a “bearing bar.” Bearing bars are typically manufactured from steel and are the components of the grating that support the weight of the load they will carry. In most cases, bearing bars are arranged in rows and spaced sufficiently apart to allow the second type of bar stock to fit in between them.

The second type of bar stock used to manufacture Industrial Steel Grating is called a “cross bar.” Cross bars are usually manufactured from steel or some other type of material and are attached to the bearing bars using a number of methods, including welding, lacing, or bolting. These bars help to keep the bearing bars in place and allow for additional support to be added if necessary.

Industrial Steel Grating has many uses in various industries throughout the world. Grating provides a way for air, water, and other materials to flow freely through it while providing support to heavy loads. Grating is found in almost every industrial sector where safety, strength, and ease of maintenance are essential.

Unlike a traditional, solid surface floor, Industrial Steel Grating provides excellent slip resistance, great visibility, and excellent ventilation. These qualities make Industrial Steel Grating an ideal solution for challenging, demanding environments found in many industrial sites across the globe.

Types of Industrial Steel Grating Used in India

1. Mild Steel Grating

The most popular type of grating in the Indian industry is mild steel grating. Mild steel grating is a cost-effective solution to many industrial applications, such as walkways and stair treads, and it can also be used as a product to cover trenches or platforms above ground level. To provide added resistance to corrosion, hot-dip galvanizing is often used for this product.

2. Stainless Steel Grating

Stainless steel grating is used in the chemical, food processing, and pharmaceutical manufacturing industries due to its superior resistance to corrosion and ability to maintain a hygienic environment. Although stainless steel grating has a higher cost than other types of grating, it will last longer in a more aggressive environment.

3. Press-locked Steel Grating

The smooth edges and consistent spacing between the grates create an attractive product that is also an extremely strong structural element, making it a great choice for commercial and utility applications where look and precision matter.

4. Heavy-Duty Load-Bearing Steel Grating

This grating is specifically designed for very high load areas such as ports, power plants, and refineries. Heavy-duty steel grating can withstand extreme loading conditions without bending or twisting.

Key Applications of Industrial Steel Grating

Industrial steel grating is utilized in numerous industries throughout India:

– Manufacturing plants and factory floors

– Oil and gas refineries and petrochemical plants

– Power generation plants and substations

– Drainage systems and trenches

– Industrial stairways, ladders, and platforms

– Warehouses, material handling areas, and pallets

The versatility of industrial steel grating is the primary reason that it is regularly chosen in applications where safety, strength, and airflow are all necessary.

Benefits of Industrial Steel Grating

High Load Strength

Industrial Steel Grates are designed to withstand heavy machinery, equipment and foot traffic without sacrificing the safety of personnel working in that area.

Safer Workplaces

The anti-slip surfaces make employees less likely to fall in areas where water and oil are regularly present; therefore, anti-slip surfaces help protect against workplace injuries that are typically sustained due to slips and falls.

Efficient Drainage & Ventilation

Industrial Steel Grates allow unwanted materials such as dirt, dust and heat to leave an area very easily by means of their open design, which helps keep work areas cleaner and safer for employees.

Long Service Life

If treated properly through the use of galvanizing, Industrial Steel Grates will resist deterioration from corrosion and wear for a great deal of time.

Cost Effectiveness in Maintenance

Due to the minimal cleaning and infrequent replacement of these products; therefore, these products require very little in terms of long-term maintenance costs.

How to Choose the Right Grating Manufacturer in India

The following criteria should be used to evaluate the selection of an industrial grating manufacturer in Gujarat or India:

Manufacturing Capabilities:

The ability to fabricate products in-house offers manufacturers the ability to maintain a high level of quality control and complete orders more quickly.

Design Customisation:

Many industrial applications require customised designs for items such as trolleys, ladders, handrails, pallets, and gratings, depending on the job site.

Compliance with Standards:

The manufacturer should comply with IS as well as international load standards such as AS and DIN.

Industry Experience:

Look for evidence of successful product designs and installation within multiple unique industry sectors.

After-sales support:

The manufacturer should offer technical assistance and consistent, reliable communication.

Partnering with an experienced manufacturer of industrial gratings will guarantee your grate will perform safely when it is subjected to the rigours of a working industrial environment.

The Importance of Customised Fabricated Components

Standard products are not compatible with many complex industrial layouts. Custom-fabricated components such as ladders, handrails, pallets, and trolleys create efficiency and improve safety in industry workflows. A manufacturer that offers a complete line of custom fabricating solutions will have the ability to provide solutions that can greatly reduce downtime and installation problems.

Frequently Asked Questions

Q1. What is the ideal material for industrial steel grating in corrosive environments?

Stainless steel or hot-dip galvanized mild steel is recommended for corrosive or chemical-exposed environments.

Q2. How long does industrial steel grating last in Indian conditions?

With proper galvanizing and installation, steel grating can last 15–25 years even in harsh industrial environments.

Q3. Is industrial steel grating suitable for heavy machinery areas?

Yes, heavy-duty steel gratings are specifically designed to handle high static and dynamic loads.

Q4. Can steel gratings be customised as per plant layout?

Absolutely. Reputed manufacturers offer fully customised sizes, load capacities, and fabricated accessories.

Q5. Why choose a local grating manufacturer in Gujarat or India?

Local manufacturers ensure faster delivery, cost efficiency, better support, and designs suited to Indian industrial conditions.

About Earth Tech Engineering Works

Earth Tech Engineering Works is a leading manufacturer of industrial steel gratings and precision-fabricated components in India. We specialise in high-quality, customised solutions including industrial gratings, trolleys, ladders, handrails, and pallets—engineered to meet the demanding needs of modern industries.

With a strong focus on quality, safety, and customization, we serve diverse sectors across India with reliable, long-lasting products.

Ready to Upgrade Your Industrial Infrastructure?

If you’re looking for durable, customised industrial steel grating or fabricated components tailored to your industry, our team is here to help.

Contact Earth Tech Engineering Works today to discuss your requirements, request a quote, or get expert guidance for your next industrial project.

Build safer, Build stronger, Build smarter—with the right grating partner.