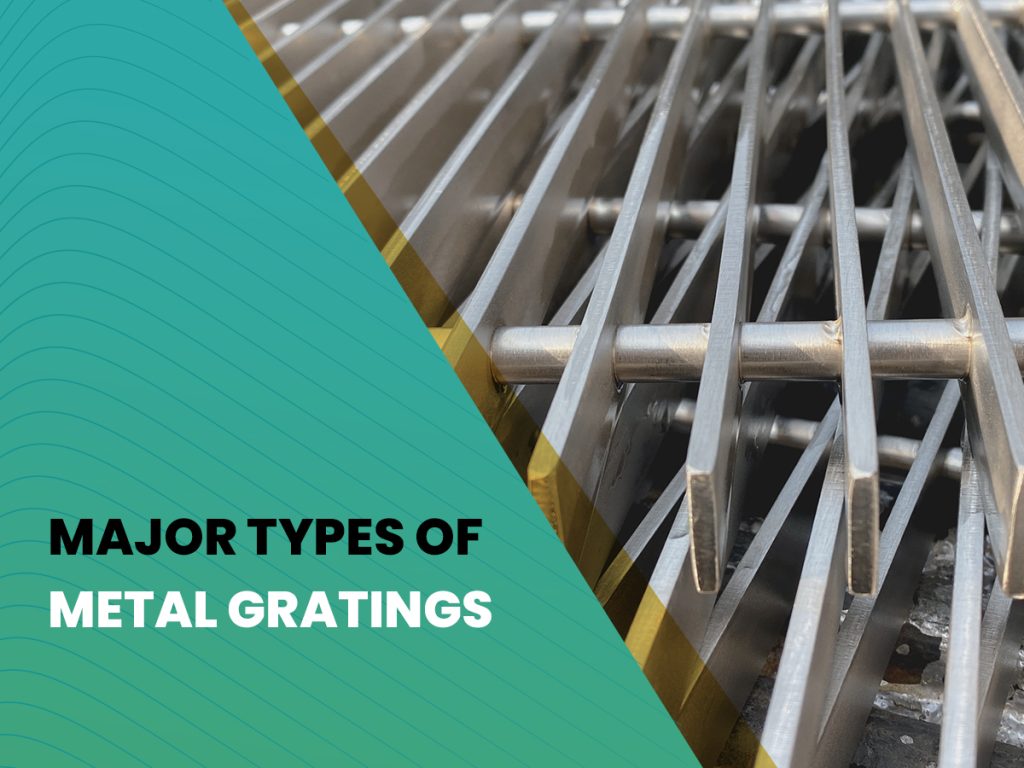

Metal gratings are structures made by connecting metal rods in a grid pattern to be used for several purposes including covering an opening on the land. These patterns are highly useful to drain water into an opening and serve many other industrial uses.

As one of the trusted Industrial Metal Grating Manufacturers, we specialize in producing durable gratings for industries across Gujarat and beyond.

Industrial gratings have multiple uses like providing ventilation when installed in a building. It also provides safe walking option on slippery water surfaces or debris. These are installed on sidewalks to drain out water logging during monsoon season. These are also used for creating shades and even for modern and abstract fashion.

Industries that use industrial gratings extensively:

- Construction sites

- Architecture

- Manufacturing businesses

- Agriculture

- Sewage treatment plants

- Safety industry

- And more

Major Types of Metal Gratings for Industrial Usage:

Leading Grating manufacturers in Vadodara, Dahej, and Ankleshwar commonly supply welded and press-locked gratings for heavy-duty flooring.

Steel floor grating:

This grating is created to form an open grid assembly of steel bars, which are joined perpendicularly to run in single direction. Their purpose is to withstand heavy loads with least weight and provide anti-slip character to the place where they are installed. They are rust-free alternative compared to other metals and provide exceptional durability. These are mainly used for floors, fencing, power stations, stair treads, trolley channels, heavy loading areas etc.

Aluminum floor grating:

As aluminum is much lighter and less strong than steel, these gratings are used when they need a lighter alternative to steel. Again, these types are rust-free and totally recyclable. They are best for industries that need light metal gratings with a high strength-to-weight ratio. It also provides an aesthetic appeal to industries that need light grid formations like architectural projects.

FRP Floor grating:

Fiberglass Reinforced Plastic (FRP) floor gratings are made through protrusion method or mold. Simply put, these are made by connecting mesh of glass fiber roving and polymer resin formed in a mold. These are highly durable due to glass fiber and offers resistance to corrosion due to the characteristics of polymer resins. They are resistant to electricity which makes them a safe option. They are non-magnetic so, saves situations which involve damage due to magnetic field. They are spark proof so do not cause accidents related to fire. Basically, a much safer option that metal gratings.

Bar grating:

These are welded steel rods arranged systematically to form rectangular grids. These are used for several industrial and commercial purposes like rooftop walkways, bridge flooring, ramps, trench covers, platforms and more. These are light weight compared to other metals and offer anti-slip and corrosion free surface. They are used in many industries like manufacturing companies, construction sites, agriculture, architecture and more.

Safety grating:

These are metal gratings formed by welding metal rods into different shapes like diamond, round and more, used mainly for safety purposes. These have 360 degrees slip resistant property with narrower holes to prevent large objects from falling through them. They are used for transportation services, truck cap steps, tower platforms, rooftop walkways and other safety related industries.

Primary Applications of Metal Gratings:

Metal walkways:

Warehouses and big manufacturing industries have multi layered buildings and structures which can be easily climbed through metal gratings which substitutes for partial flooring. They are safe, provide traction and offers safety of employees when they walk through wet surfaces. They also add aesthetic appeal to create rooftop walkways and even supports objects from falling from a height.

Creates rust-free surfaces:

Provides a rust proof, stain-free flooring for industrial setups. Companies don’t need to clean up flooring in the events of spillage of water or chemicals. The grating remains strong, resistant and durable for years at length. Stainless steel gratings are best for creating corrosion free floorings.

For air circulation and better visibility:

Solid platforms or stairs block light while metal gratings allow passage of light through them to create a well-lit space. Again, these are best used for creating well ventilated places as air gets easily circulated through them. They are very helpful in preventing claustrophobic conditions at manufacturing sites. They contribute to safety of employees at places with heavy structures and big machinery.

To create visual aesthetics:

Metal gratings are used in buildings and art spaces to create atypical visual appeal. They provide safety along with enhancing the aesthetic value of the place. Shopping centers, commercial and modern buildings can be embellished with these gratings to create a unique ambience.

Conclusion

Metal gratings have versatile applications and are best suited to create safer places for industrial and commercial environment. Made of high-quality metal and installed in the right place, they remain strong for years at length. Use them when you need to create walkways and other perforated metal structures for a long time. Whether you need metal gratings in Ahmedabad, GIDC Manjusar, or GIDC Makarpura, Earth Tech Engineering is your go-to Industrial Metal Grating Manufacturer in Gujarat.