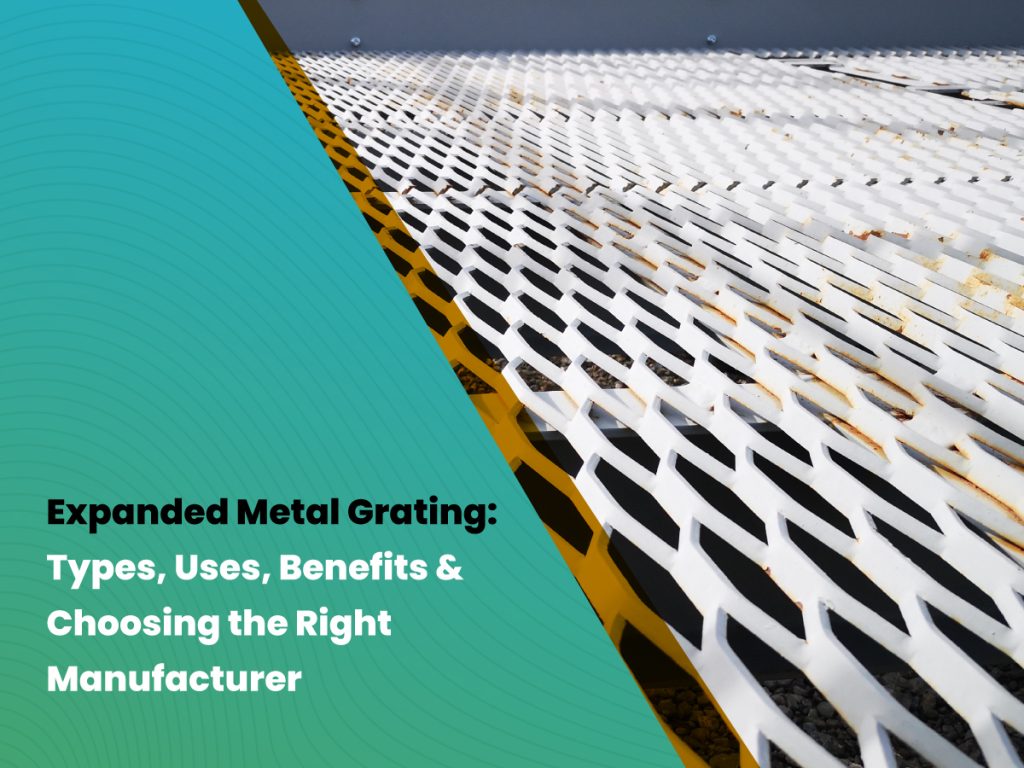

Expanded metal gratings are a versatile and cost-effective solution for industrial and other types of environments where durability, safety, and airflow are critical factors. this grating is used to construct walkways, platforms, staircases, and barriers across all Indian industry sectors due to the inherent slip resistance, low maintenance requirements, and high strength properties of this type of grating.

This guide will provide an overview of what expanded metal grating is, how it is produced, the benefits associated with its use, and finally, how to find a quality expanded metal grating manufacturer in India, particularly if you intend to purchase your grating from Gujarat, India’s predominant manufacturing centre.

What Is Expanded Metal Grating?

Expanded Metal Grating is produced by cutting a single sheet of metal and then stretching it in order to produce an open diamond-shaped mesh structure. The slitting and stretching process strengthens the sheet without adding any additional materials, while also maintaining an adequate level of light and air flow as well as allowing excess moisture, dirt, and debris to drain easily through the open structure.

In contrast to traditional bar-type gratings, expanded metal grate has the ability to evenly distribute loads across the entire width of the sheet, creating a product that has increased rigidity, is safer to use, and will withstand harsher conditions that are typically found in the industrial sector.

Materials Commonly Used in Expanded Metal Grating

This Gratings can be manufactured with many different metals, depending on how they will be used and where they will be installed, including:

Mild Steel (MS): Very Economical, ideal for Heavy Industrial use

Stainless Steel: Resistance to Corrosion; Ideal for Chemical, Food, and Pharmaceutical Industries

Aluminum: Lightweight and Corrosion-Resistant for Use in Infrastructure and Architectural Applications

Galvanized Steel: Increased Durability for Use in Outdoor and High-Moisture Environments

A reliable Grating Manufacturer in Gujarat will assist in selecting an appropriate Grating Material based upon: Grating Load, Grating Exposure, Grating Compliance, and Product Application.

Key Benefits of Expanded Metal Grating

1. Lightweight But Strong

As expanded metal is formed from expanding to a larger surface area, it helps to improve the strength of the metal for more significant load-bearing capabilities than can be accomplished without expanding the metal, thus reducing the amount of material needed to create expanded grating.

2. Exceptional Slip-Resistance

The raised diamond mesh pattern gives the expanded metal grate surface a natural traction point, which helps to reduce slip and fall accidents in manufacturing plants and other commercial settings.

3. Exceptional Airflow & Drainage

Due to the open mesh design, this grating allows air, moisture and dust to pass freely through it, making it a perfect choice for industrial flooring and floor walkways.

4. Minimal Maintenance & Exceptional Longevity

With fewer joints and optional coatings or galvanizing, this grating has a much longer service life than traditional grating systems that require a great deal of maintenance.

5. Production Cost Savings

Because this grating is produced without the use of welding or secondary operations, it provides significant savings on the cost of producing and installing traditional grating systems.

Industrial Applications of Expanded Metal Grating in India

Across the Indian industrial sector, expanded metal grates used in:

– Industrial walkways/platforms

– Stair treads/safety ladders

– Machinery guards/safety enclosures

– Power plants/refineries

– Chemical/process industries

– Warehouses/logistics facilities

– Infrastructure/construction projects

Many projects using expanded metal grate also use custom trolleys, handrails, ladders and pallets to provide complete industrial access and material handling systems.

Expanded Metal Grating vs Traditional Grating

Compared to traditional bar grating, expanded metal grate provides:

– No welded joints, hence it has greater structural integrity

– Excellent slip resistance

– Lower weight overall

– Less raw material waste

– Neater appearance for visible installations

The above advantages have led to expanded metal grating becoming the material of choice for most current industrial and infrastructure projects in India.

Why Gujarat Is a Hub for Grating Manufacturing

Gujarat is one of India’s leading states for advanced fabrication facilities. If you’re looking for a grating manufacturer based in Gujarat, you will experience the following benefits:

– Access to skilled fabrication expertise

– Accelerated delivery timelines and production speed

– Lower cost based on industrial-scale production

– Bow to all Indian and International quality standards

Many of the largest grating manufacturers in India are located in Gujarat and supply products throughout the entire country.

How to Choose the Right Grating Manufacturer in India

Before finalising a supplier, consider:

– Fabrication Capabilities: Ability to cut, expand and finish all in-house.

– Design Support: Can the manufacturer create a product based on load and site-specific designs?

– Quality: Are all raw materials and coatings certified for quality?

– Experience: Does the manufacturer have a successful track record in multiple sectors?

– After Marketing Support: Is technical support and documentation available after the sale?

A company that provides both standard and custom-designed products helps ensure long-term value for customers.

Frequently Ask Questions

Q1. What is expanded metal grating used for?

Expanded metal grating is used for industrial flooring, walkways, stair treads, platforms, machine guards, and safety structures where strength and slip resistance are required.

Q2. Is expanded metal grating stronger than welded grating?

Yes. Since it is made from a single metal sheet without welding, expanded metal grate offers higher structural integrity and uniform load distribution.

Q3. Which is the best material for expanded metal grating in India?

Mild steel is most commonly used for industrial applications, while stainless steel and aluminium are preferred for corrosive or lightweight requirements.

Q4. Why choose a grating manufacturer in Gujarat?

Gujarat manufacturers offer advanced fabrication capabilities, competitive pricing, and faster delivery due to strong industrial infrastructure.

Q5. Can expanded metal grating be customised?

Yes. Reputed grating manufacturers in India provide customised sizes, thicknesses, load ratings, and finishes based on project needs.

About Earth Tech Engineering Works

Earth Tech Engineering Works is the premier Metal Grating Manufacturer and Industrial Fabrication Manufacturer in India. Our focus on Quality, Precision and Customisation enables us, as a full-service Manufacturer of Industrial Gratings, Custom Made Trolleys, Ladders, Handrails and Pallets, to provide. If you are interested in purchasing Expanded Metal Grating, please contact us for a quick, free, no-obligation quote and information on where to begin your project.

Ready to Source Reliable Expanded Metal Grating?

If you are looking for a trusted, safe, strong and long-lasting solution, Earth Tech Engineering Works can help you with your needs for standard Industrial Gratings and Custom Fabricated Components.

👉 Contact us today for Technical Support, Request For Information, Request For Quotation and See More Grating Manufacturers in India.