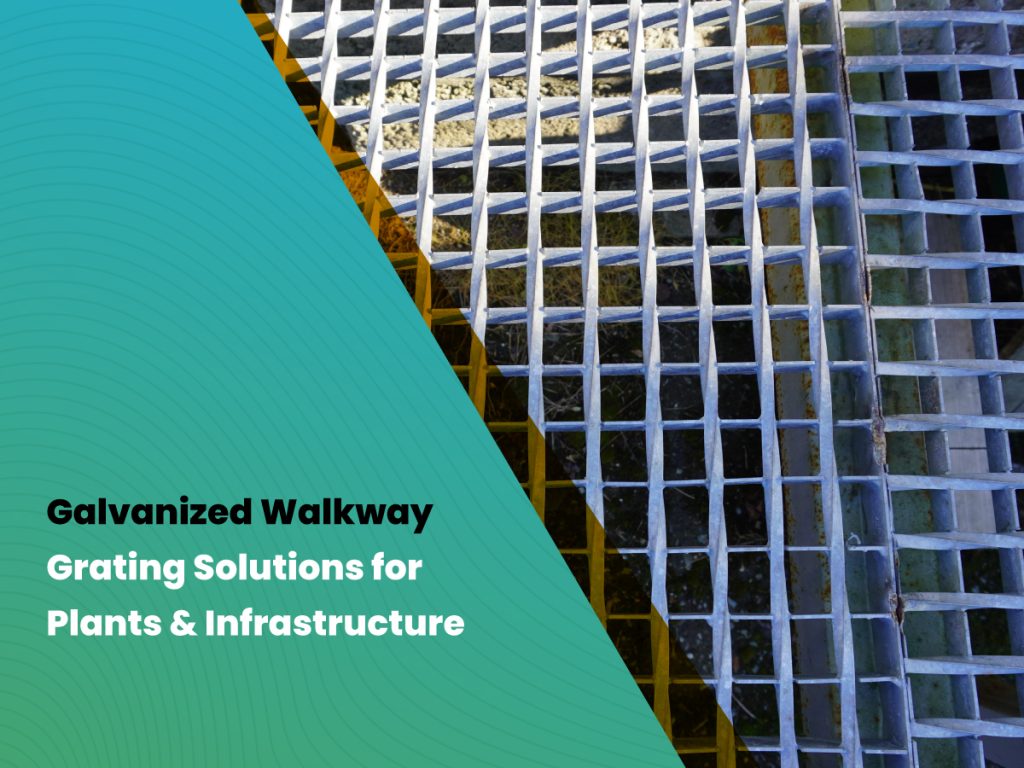

Galvanized Walkway Grating

The safest part of an industrial facility is typically the walkways. Corridor systems provide easy access; however, they also enhance safety for all workers by providing a safe walking surface. Galvanized walkway grating is made from galvanized steel and provides a sturdy, corrosion-resistant, low-maintenance walkway system for plant managers, EPC contractors, and other industrial facilities throughout India. The type of grating you select as a facility manager will directly affect worker safety, downtime, and increasing cost efficiencies for your organisation over time.

What Is Galvanized Walkway Grating?

Galvanized walkway grating refers to a system of steel gratings that can be used at an elevated height as well as at ground level to construct walkways, platforms, and access routes. The steel is hot-dip galvanized after being manufactured. This process creates a coating of zinc that protects the steel from deterioration due to exposure to moisture, chemicals, and other environmental elements.

In India, industrial settings are characterized by significant humidity, heat, dust, and various types of chemicals. As such, a Galvanized Grating product will provide a consistent level of performance for decades with a significant amount of service.

Why Is Galvanization So Important To Safety In Regards To Walkways?

The galvanizing process is not simply a cosmetic application, it provides a functional layer for safety.

- Corrosion Resistance: Because the galvanizing process creates a coating of zinc, any steel that is galvanized does not rust in coastal regions, chemical facilities or in high-moisture areas.

- Extended Life Cycle: Galvanized walkway grating can last significantly longer than painted and untreated steel products.

- Load Carrying Capacity: Galvanized walkway grating does not lose its load-carrying ability through time as opposed to uncoated steel products.

- Minimal Maintenance: The need for repainting and replacing products are minimized, which means greater savings in the cost and time spent maintaining a plant and less downtime

Galvanization is a guarantee for safety engineers to verify that the walkway systems maintain their structural integrity and are slip-resistant throughout their anticipated use.

Types of Galvanized Walkway Gratings

Various types of grating are used in different industrial applications, some of which include:

Press-Locked Galvanized Grating

This grating is created using cross bars that are inserted under pressure giving them a clean appearance and a way to distribute a uniform load. Press-locked gratings are often used for walkways in chemical plants and clean industrial environments.

Welded Steel Grating

Welded steel grating is the strongest and most rigid type of grating, making it an ideal option for heavy traffic and access to equipment in power plants and manufacturing plants.

Serrated Galvanized Grating

The serrated surfaces increase the slip resistance of the grate, making them ideal for wet/oily and/or chemical-exposed environments. Serrated gratings are used frequently in refineries and offshore applications.

Heavy-Duty Industrial Grating

designed for very high loads, heavy-duty walkway gratings are common in large infrastructure projects, on conveyor access routes, and in large industrial spaces.

Manufacturing Process (India-Focused)

All walkway gratings must be manufactured utilizing a controlled process to ensure reliability.

Raw Material Selection

Structural steel flats and bearing bars are selected to manufacture walkway gratings based upon the loads and spans required by the customer.

Fabrication

Walkway gratings are manufactured via cutting, welding or the press-locking process depending upon the engineering drawing and project specifications provided.

Hot-Dip Galvanizing

When finished, gratings are immersed in molten zinc to coat the entire grating even at joints and edges, for maximum corrosion resistance. The coating thickness must meet Indian standards for durability.

Quality Assurance

All gratings are inspected for dimensional accuracy, coating thickness, weld integrity and load performance before they are shipped to customers.

End-to-End Control

Only those companies that source raw materials directly from a manufacturer can ensure the highest level of quality control during the manufacturing process.

Applications Across Industries

Indian industry employs Galvanized walkways in many fields, including;

- Chemical plants: gratings prevent corrosion on walkways for reactors

- Piping Oil & Gas: Safe access platforms for hazardous environments

- Power Plants: Maintenance access walkways for turbines and boiler areas

- Infrastructure Projects: Access for bridges, drainage maintenance, and repairs, and service access walkways

- Warehouses/Factories: Access routes between mezzanine floors and material handling areas.

Load Bearing, Standards & Safety

Industrial walkways must be constructed to support both static (constant) and dynamic (growing over time) loads. The way the industrial walkway is designed should include the following:

- Load Capacity: The number of feet impacts the number of people walking on them, carrying tools, and the occasional movement of equipment.

- Span Length: The distance from one supporting crossbar to another impacts crossbar size selection.

- Slip Resistance: If water or oil is present on the surface of the walkways, they will require serrated surfaces.

- Indian usage conditions: How the walkways will be used based on conditions specific to India (temperature, dust, chemicals) and what types of products will be transported or stored.

Working with a manufacturer will ensure that you engineer your walkway—rather than just guess—to achieve the safety requirements of the application.

Why Choose a Manufacturer Over a Trader

The advantages of sourcing directly from a grating manufacturer in Gujarat for industrial projects are clear-cut:

- Customisation: Everything (size, load rating, surface finish, and layout) can be made exactly to the needs of the job.

- Quality Control: The manufacturer supervises both the fabrication and galvanizing of the products.

- Reliability for the Project: The manufacturer provides assurance of on-time delivery, provides technical support when needed, and has all documentation.

The majority of traders will be selling standard products, whereas manufacturers sell engineered solutions.

Why Earth Tech Engineering

Earth Tech Engineering provides custom galvanized walkway grating for demanding industrial environments. With over 20 years of experience in engineering, design, and manufacturing for heavy-duty applications, the company produces custom products using advanced techniques, state-of-the-art equipment, and strict quality management.

- Custom-Made Walkway Systems

- Heavy Duty Walkway Design & Fabrication for Long Lasting Use

- Integrated with (ladders, handrails, trolleys, and pallets)

- High Quality Walkway Products that Meet Indian Industrial Standards

The advantages of Earth Tech Engineering to EPC Contractors and Plant Owners are increased safety for workers on walkways and an enhanced level of confidence when executing projects successfully.

Frequently Asked Questions

Q1. What is the typical lifespan of galvanized walkway grating?

In industrial conditions, hot-dip galvanized grating can last 20–30 years with minimal maintenance.

Q2. Is galvanized grating suitable for chemical plants?

Yes. The zinc coating provides strong resistance against moisture and many industrial chemicals.

Q3. How do I select the right load capacity for walkways?

Load selection depends on foot traffic, equipment weight, and span length. Manufacturer consultation is recommended.

Q4. What is the difference between welded and press-locked grating?

Welded grating offers higher strength, while press-locked grating provides a cleaner finish and uniform spacing.

Q5. Is a serrated grating necessary for all walkways?

Serrated grating is recommended in wet, oily, or chemical-exposed areas for better slip resistance.

Q6. Can galvanized walkway grating be customized for site layouts?

Yes. Manufacturers can fabricate gratings to exact dimensions, cut-outs, and access requirements.