Providing Durable and Reliable Metal Grating Solutions for Industrial Applications

At Earth Tech Engineering, we take pride in being the most trusted and reliable Metal Gratings Manufacturer in India. With years of experience, state-of-the-art technology, and a dedicated team, we have been able to provide our clients with top-quality industrial metal gratings for a wide range of applications. Our commitment to excellence has made us the preferred choice for numerous industries across the nation.

What Are Industrial Metal Gratings?

Industrial metal gratings are a versatile and essential component used in various industries for diverse metal gratings applications. They consist of a framework of parallel and perpendicular metal bars, which are welded, swaged, or pressure-locked together to form a rigid, open grid structure. The openings, or spaces between the bars, allow for efficient drainage, ventilation, and passage of light, while the grid pattern provides strength, stability, and slip resistance.

They are designed to withstand heavy loads, resist corrosion and provide excellent traction, making them ideal for use in harsh environments such as chemical plants, oil rigs, and food processing plants. As an industrial metal gratings manufacturer in India, we specialize in providing a wide range of metal gratings solutions that cater to various industrial applications.

Types Of Industrial Metal Gratings We Manufacture:

Our extensive range of metal gratings is designed to cater to the diverse needs of various industries. We offer a comprehensive selection of materials, patterns, and sizes to ensure that you find the perfect solution for your project. Our product line includes:

Manual Welded Steel Bar Grating

Tank Treads & Landings

Drain Gratings

Designed for strength and durability, these gratings are ideal for walkways, platforms, and other heavy-duty applications.

Customized solutions for safe access and maintenance of storage tanks in various industries, ensuring worker safety and efficient operations.

These gratings are perfect for drainage systems, allowing for effective water management in industrial, commercial, and public settings.

Stainless Steel Gratings

Heavy Duty Gratings

Steel Trench Cover Gratings

Known for their corrosion resistance and high strength, these gratings are suitable for environments with stringent hygiene requirements, such as food processing and chemical plants.

Engineered to withstand heavy loads and traffic, these gratings are designed for demanding industrial applications where durability is crucial.

These durable and robust steel gratings provide safe and secure covers for trenches, offering easy access for maintenance and ensuring workplace safety.

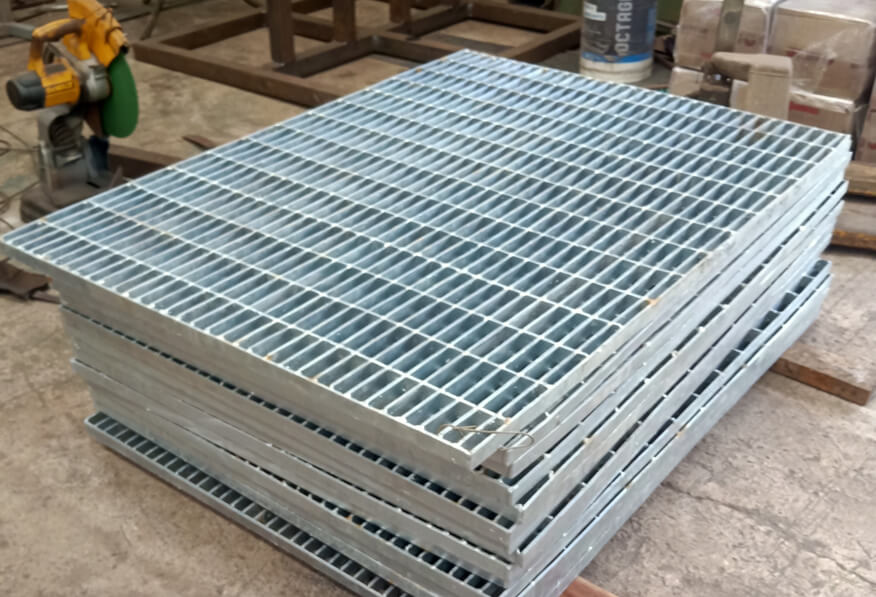

Galvanized Gratings

Galvanized Iron Grating

Interlock Gratings

These gratings undergo a galvanization process, which adds a protective zinc coating to prevent rust and corrosion, making them ideal for outdoor applications.

A cost-effective and durable solution for various industrial applications, these gratings offer excellent strength and corrosion resistance.

These gratings are designed with a unique interlocking system that allows for easy installation and removal, making them ideal for temporary or modular applications.

SS Antiskid Gratings (Serrated) / Expanded Metal Walkway Grating

Featuring a serrated surface, these stainless steel gratings provide exceptional slip resistance, ensuring safety in wet or oily conditions.

Expanded metal walkway grating is a type of industrial flooring made from sheet metal that has been cut and stretched into a pattern of diamond-shaped openings. This creates a strong and durable surface that allows for easy drainage of liquids and small debris, making it ideal for use in outdoor and industrial settings where slip resistance and safety are a concern. The grating is commonly used in walkways, platforms, stair treads, and other applications where a non-slip surface is required. It is available in a variety of materials, including aluminum, steel, stainless steel, and galvanized steel, and can be customized to meet specific size and shape requirements.

How To Choose Metal Gratings?

| Steps | How to Choose Metal Gratings |

| 1 | Determine the Application: Understand the project requirements and installation environment. |

| 2 | Select the Material: Choose the appropriate material based on strength, weight, and corrosion resistance. |

| 3 | Choose the Grating Type: Select the grating type based on load-bearing capacity and project requirements. |

| 4 | Determine the Bearing Bar Size and Spacing: Consider load-bearing capacity and support requirements. |

| 5 | Select the Finish: Choose a suitable finish for appearance and durability. |

| 6 | Calculate the Load and Deflection Requirements: Ensure the grating meets load and deflection criteria. |

| 7 | Consult with a Professional Grating Manufacturer: Discuss project requirements, get advice, and receive a quote. |

Patterns Of Industrial Gratings We Manufacture:

Rectangular Grid Pattern:

Diamond Pattern:

Serrated Pattern:

The most common pattern, featuring parallel bearing bars and perpendicular cross bars, providing optimal strength and support.

Characterized by diagonal bearing bars intersecting with diagonal cross bars, offering a visually appealing and slip-resistant surface.

Designed with notched bearing bars to enhance slip resistance, making it ideal for wet or oily environments.

I-Bar Pattern:

Riveted Pattern:

Pressure-Locked Pattern:

Features unique I-shaped bearing bars, providing high strength with reduced weight, making it suitable for lightweight structures.

Comprises bearing bars connected to cross bars with rivets, offering increased load capacity and durability, ideal for heavy-duty applications.

Created by interlocking bearing bars and cross bars under high pressure, resulting in a smooth and uniform appearance.

Circular Gratings:

Zigzag Honey Comb Gratings:

Custom Patterns:

These gratings feature a radial pattern of bearing bars and circular cross bars, providing an attractive and functional design. Circular gratings are often used for covering round openings, such as manholes or drainage systems, as well as for decorative purposes in architectural applications.

This distinctive pattern consists of zigzag-shaped bearing bars interconnected with cross bars in a honeycomb-like configuration. The unique design offers excellent slip resistance and drainage efficiency, making it suitable for various applications such as walkways, platforms, and stair treads.

Tailored to meet specific project requirements, these patterns can be designed to match unique aesthetic preferences or to address functional needs, ensuring the perfect combination of style, functionality, and performance.

Earth Tech Engineering Grating Specification:

We pride ourselves on offering high-quality metal gratings that meet the specific needs of our clients. Our grating specifications are designed to ensure optimal performance, durability, and safety.

Key Specifications Includes:

| Specification | Description |

|---|---|

| 1. Material Options | Steel, stainless steel, aluminum, and galvanized steel, chosen based on the application and environmental conditions. |

| 2. Grating Types | A wide variety, including welded bar, serrated, interlocking, I-bar, riveted, pressure-locked, circular, and zigzag honeycomb gratings. |

| 3. Patterns | Rectangular grid, diamond, serrated, I-bar, custom patterns, and more to cater to diverse applications and aesthetics. |

| 4. Bearing Bar Size | Available in a range of sizes, typically from 20mm x 3mm up to 75mm x 6mm, depending on load-bearing requirements and project specifications. |

| 5. Bearing Bar Spacing | Options such as 30mm, 40mm, or 60mm, ensuring the right balance between support, drainage, and slip resistance. |

| 6. Cross Bar Size | Varies based on the grating type and load requirements, ensuring optimal stability and support. |

| 7. Cross Bar Spacing | Options include 50mm, 100mm, or custom spacing to suit project needs and design preferences. |

| 8. Load & Deflection | Engineered to meet the specific load-bearing capacity and deflection limits of your project. |

| 9. Finishes | A variety of finishes, such as mill, painted, galvanized, or powder-coated, to enhance appearance and protect against corrosion. |

| 10. Customization | Expert consultation and tailored solutions to meet unique project requirements, including custom sizes, patterns, and materials. |

| 11. Chemical Reactivity | Manufactured using materials with low chemical reactivity for environments with exposure to chemicals, acids, or corrosive substances. |

Industrial Application of Metal Gratings:

| Application | Description |

|---|---|

| Warehouses | Metal gratings serve as durable and slip-resistant flooring solutions for warehouses, providing safe access to storage areas and facilitating efficient material handling. |

| Manufacturing Industries | Metal gratings are widely used in various manufacturing industries as walkways, platforms, and workstations, ensuring the safety of workers and optimizing workflow. |

| Safety Purposes | Metal gratings are often employed as safety barriers, railings, or guardrails to protect workers and prevent accidents in industrial and commercial settings. |

| Drains | Metal gratings are commonly used as drain covers in both indoor and outdoor environments, effectively preventing debris from clogging drainage systems while allowing water to pass through. |

| Machinery & Equipment | Metal gratings can be utilized as protective guards for machinery and equipment, providing ventilation and visibility while ensuring the safety of workers. |

| Bridges and Infrastructure | Metal gratings are used in the construction of bridges, pedestrian walkways, and other infrastructure projects, offering a durable and cost-effective solution that can withstand heavy loads and harsh environmental conditions. |

| Walkways & Platforms | Metal gratings are commonly used as walkways, platforms, and mezzanine flooring in industrial facilities, providing safe and slip-resistant access for workers. |

| Ventilation Grilles | Metal gratings are frequently used as ventilation grilles in various industrial environments, allowing for optimal airflow while providing a protective barrier. |

| Stairs & Treads | Serrated or slip-resistant metal gratings are often used as stair treads in commercial and industrial buildings, ensuring a secure footing for employees and visitors. |

| Ramps and Loading Docks | Metal gratings provide durable, slip-resistant surfaces for ramps and loading docks, ensuring safe and efficient transportation of goods and equipment. |

| Catwalks | Metal gratings are utilized as catwalks in industrial facilities, offering a lightweight and durable access solution for workers. |

| Chemical & Petrochemical | Due to their corrosion-resistant properties, stainless steel or aluminum gratings are commonly used in chemical and petrochemical plants, ensuring longevity and safety in harsh environments. |

Advantages Of Earth Tech Engineering Metal Gratings:

As a leading Metal Gratings Manufacturer in India, we understand the importance of quality and durability in industrial applications. Our products are meticulously crafted using the highest quality raw materials, ensuring that they meet and exceed international standards. Our gratings undergo rigorous testing to guarantee their performance, longevity, and resistance to corrosion, making them a reliable choice for your industrial needs.

| Durability | Corrosion Resistance | Slip Resistance | Customization | High Load Capacity |

| High-quality materials ensure long-lasting performance even in the most demanding environments. | Variety of finishes, such as galvanized or stainless steel, provide excellent corrosion resistance. | Slip-resistant surfaces improve safety for employees and visitors, reducing the risk of accidents. | Expert consultation and customization options, including custom sizes, patterns, and materials. | Engineered to support heavy loads, making them ideal for various industrial applications. |

| Easy Maintenance | Versatility | Aesthetic Appeal | Cost-Effective | Fast Installation |

| Easy to clean and maintain, reducing long-term maintenance costs and minimizing downtime. | Suitable for a wide range of applications, offering a versatile solution for diverse project needs. | Available in various patterns and finishes, adding visual interest and enhancing the overall aesthetic of your project. | Durable and long-lasting solution at a competitive price, offering excellent value for money. | Designed for quick and easy installation, reducing labor costs and project timelines. |

Why Choose Earth Tech For Custom Metal Gratings Manufacturing In India?

When it comes to custom metal gratings manufacturing, Earth Tech stands out as the leading choice in India for several reasons. Here’s why you should choose Earth Tech for your metal grating needs:

| Industry Expertise | High-Quality Materials | Cutting-Edge Technology | Comprehensive Service | Competitive Pricing |

| With years of experience in the metal gratings industry, our team of experts possesses the knowledge and skills necessary to provide you with the best solutions tailored to your specific project requirements. | We use only the highest quality materials in our manufacturing process, ensuring that our metal gratings are durable, long-lasting, and suitable for various applications and environments. | Our state-of-the-art manufacturing facilities and advanced technology allow us to create custom metal gratings with precision and accuracy, ensuring a perfect fit for your project. | From consultation and design to manufacturing and installation, Earth Tech offers a complete range of services to ensure a seamless experience for our clients. | We understand the importance of budget constraints and strive to provide our clients with cost-effective solutions without compromising on quality. |

| Customer Satisfaction | Quick Turnaround Time | Commitment to Safety | Environmental Responsibility | Pan-India Presence |

| At Earth Tech, we prioritize customer satisfaction and work closely with our clients to ensure that their needs are met and expectations exceeded. | Our efficient manufacturing processes and dedicated team ensure that we can deliver custom metal gratings within short timeframes, helping you keep your project on schedule. | We are dedicated to providing safe, slip-resistant metal gratings that adhere to the highest safety standards, ensuring the well-being of employees and visitors alike. | Earth Tech is committed to sustainable practices and minimizing our environmental impact, making us an eco-friendly choice for your metal grating needs. | With a strong presence throughout India, we can cater to clients in any region, ensuring timely delivery and consistent quality. |

Price Of Metal Gratings In India?

The price of metal gratings in India can vary depending on several factors such as the material used, the size and thickness of the gratings, the type of surface finish, and the quantity ordered. The price can also vary based on the supplier and location.

The price of metal gratings in India can range from INR 150 to INR 500 per square foot, This is just a rough estimate and the actual price can vary based on the specific requirements and market conditions. It’s important to get a quotation from different suppliers and compare prices to get the best deal for your location.

At Earth Tech Engineering, we believe in providing tailored solutions to meet the unique requirements of each project. Our team of skilled engineers and designers work closely with you to understand your needs and develop custom metal gratings that perfectly align with your specifications. Whether you require specific materials, patterns, or sizes, we are here to deliver exceptional solutions that exceed your expectations.

Same Day Site Visit For Custom Metal Gratings Requirement In The Following Cities:

| Ahmedabad | Vadodara |

| Anand | Gandhinagar |

We have successfully delivered gratings for industries like Construction, Marine, Manufacturing, Food Production Units, Manufacturing, Transportation & Infrastructure.

Our Comprehensive Metal Gratings Manufacturing Process:

Earth Tech Engineering has come a long way since its inception, evolving from a small-scale metal grating manufacturer to a leading provider of customized metal gratings in India. Our journey reflects our dedication to innovation, quality, and customer satisfaction.

| Requirement Analysis | We begin by assessing our client’s specific needs, including the desired grating type, material, finish, and dimensions. This helps us understand the project’s unique requirements and provide a tailored solution. |

| Consultation | Our team of experts works closely with the client to discuss their requirements, provide guidance, and offer recommendations based on their application, budget, and design preferences. |

| Sample Grating Providing To Client For Examination | We provide a sample grating to the client for their examination, allowing them to assess the quality, design, and finish of our product before committing to a full order. |

| Site Visit For Dimension And Environment Studying | Our team conducts a site visit to take accurate measurements, study the installation environment, and identify any potential challenges or requirements that may impact the manufacturing process. |

| Gratings Manufacturing Starts | Once all details have been finalized, our state-of-the-art manufacturing facilities begin producing the custom metal gratings, ensuring precision, quality, and adherence to the client’s specifications. |

| Delivery | After the manufacturing process is complete, we deliver the finished metal gratings to the client’s location, ensuring timely delivery and proper handling of the products. |

| Installation | Our skilled installation team installs the metal gratings at the client’s site, ensuring a seamless and secure fit, while adhering to all safety standards and best practices. |

| Maintenance | Earth Tech Engineering provides ongoing maintenance support, helping clients keep their metal gratings in optimal condition and prolonging their lifespan. |

For top-quality industrial metal gratings and unparalleled customer service, choose EarthTech Engineering as your Metal Gratings Manufacturer in India.

Contact us today to discuss your requirements and receive a competitive quote for your project. We look forward to partnering with you and helping you achieve success in your industry.