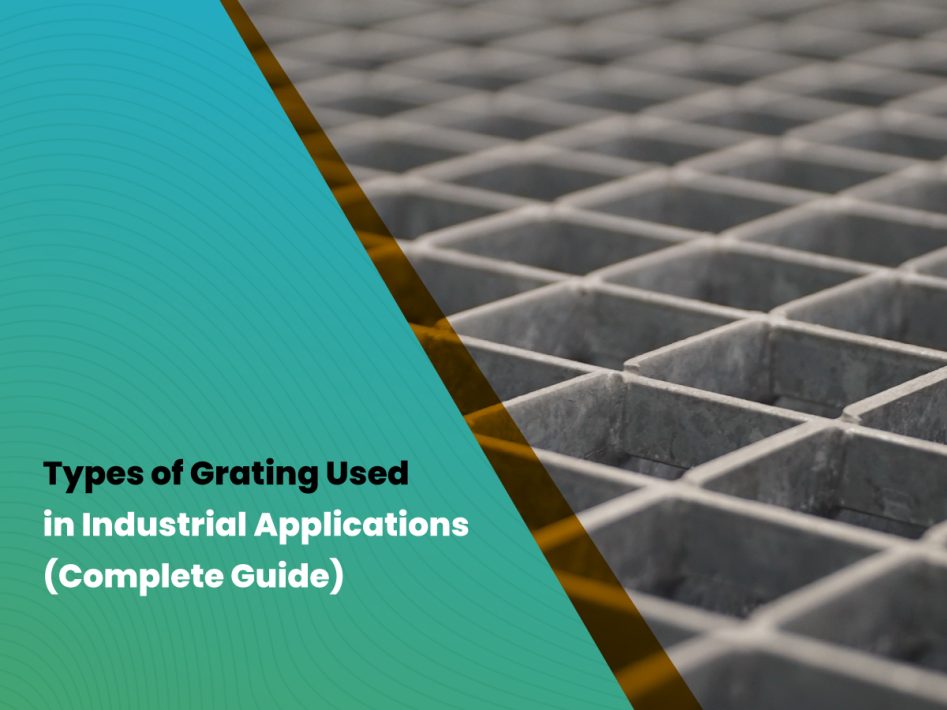

Types of Grating

In industrial settings, several different types of grating exist. These include: bar gratings, expanded metal gratings, perforated metal gratings, and safety gratings. Each design has unique load capacities, construction/engineering potential (environment), and uses depending on its intended purpose, e.g., walkways/platforms/trenches/drains & industrial floors. Therefore, selecting an appropriate type requires consideration of the load that will be applied, the exposure to different elements, and the required safety measures.

What Is Industrial Grating and Why It Matters

Industrial gratings are defined as ‘open grid flooring systems that allow air/water/dust/ and or chemicals to pass through them’ while holding (or supporting) people, equipment and materials. They have been designed specifically for use in an industrial environment rather than for aesthetic (or decorative purposes), therefore they offer greater strength and durability along with increased levels of safety. Industrial gratings also have longer life expectancy than architectural gratings because of the environment in which they are normally used.

Industrial gratings are required throughout a wide variety of industries including; factories, chemical manufacturing facilities, power plants, shipyards and large infrastructure projects.

There are several important advantages to using industrial gratings:

- to help prevent the formation of standing water/causing rust

- improve worker safety by providing good traction between the feet and the surface on which workers walk

- to support heavy equipment and foot traffic

- reduce structural weight while providing sufficient strength.

Selecting an inappropriate industrial grating could result in early failure, increase chances of serious injury/loss of life, and increase maintenance costs; therefore, it is imperative to select the correct type.

Main Types of Grating Used in Industry

Bar Grating

Bar Grating is one of the most common types of industrial grating. It’s characterized by its high Load-Bearing Capacity (LB) and stiffness (Density). Bar grating is made up of parallel, longitudinal bars that support it during use and run perpendicular to the longitudinal bars. The parallel bars are typically connected using Cross Bar Welding or Press Locking.

Key advantages:

- Very High Strength to Weight Ratio

- Available in 3 Different Load Classes (Light, Medium, Heavy-Duty).

- Easy to install and maintain.

Common applications include:

Walkways, Platforms, Mezzanines (an elevated area), Stair Treads, and Trench Covers.

Expanded Metal Grating

Expanded metal grating is a manufactured product that is produced by cutting the Steel Sheets to a predetermined size, stretching them to a specified thickness, and then cutting the individual sheets again in a manner that will produce a Diamond Shape Opening. Expanded metal grating is less heavy than bar grating, but provides good support under loads.

Key Advantages:

- Lightweight and Cost-Effective.

- No Welded Joints (Single Continuous Piece).

- High Air Flow and Drainage Potential.

Common applications include:

Outside Walkways, Fencing Panels, Equipment Guardrails, and Maintenance Platforms.

Perforated Metal Grating

Grating is a type of metal panel that has holes punched into it in an array of either controlled, or custom designs. As compared to bar grating the structural strength (load bearing capabilities) are lower, but grating has a high air to material flow ratio which allows for more air flow and flexibility in design.

Key Advantages:

- Customizable hole designs and sizes

- Smooth surface finishes for specialized uses

- Capable of allowing for controlled ventilation

Common applications include:

Drain Covers, Machine enclosures, Ventilation Panels, and Crossover architectural/industrial applications.

Safety Grating

Safety grating is specifically engineered and designed to create a high slip resistant surface in industrial or manufacturing environments where slip resistant surfaces are extremely critical. Safety grating is generally defined by its serrated or ridged surface areas and aggressive open grid patterns.

Key Advantages:

- Excellent slip resistance

- Performs exceptionally well in conditions with high amounts of water, oil and chemicals

- Improves worker safety.

Common applications include:

Chemical plants, Offshore facilities, Refineries, Wastewater treatment plants, and Loading Areas.

Types of Grating Based on Material

Material choice can have a large impact on both how well and how long something will perform.

Mild Steel Grating: Strong yet inexpensive. This is why mild steel gratings are commonly used in heavy industry.

Galvanized steel gratings: These are also affordable, but they have a significant advantage; They do not corrode when exposed to moisture or outdoor humidity.

Stainless Steel Grating: For those that work with chemicals or in the food or pharmaceutical manufacturing industries, stainless steel gratings are an excellent choice due to their anti-corrosive properties.

It is important to consider both how much exposure and what types of environmental hazards the material will be exposed to and how much maintenance is anticipated for the material before selecting.

Comparison Table – Choosing the Right Grating Type

| Grating Type | Load Capacity | Slip Resistance | Best Use Case |

| Bar Grating | High | Medium | Platforms, walkways, mezzanines |

| Expanded Metal | Medium | Medium | Outdoor flooring, maintenance access |

| Perforated Grating | Low–Medium | Low | Ventilation, drain covers |

| Safety Grating | Medium | High | Wet, oily, hazardous environments |

How to Choose the Right Type of Grating for Your Application

When choosing different types of grating, please keep some of these industrial items in mind:

Load Requirements: What are your load requirements? – Static loads, dynamic loads, foot traffic; what is the weight of the equipment going to be?

Environment: Will you have exposure to chemicals, moisture, heat, or ocean/marine conditions?

Location of Installation: Is it going to be for walkways, trenches, elevated platforms (i.e. catwalks), or drainage?

Safety Features: Does it need to provide some slip-resistant features? Edge visibility; Do I need to comply with any regulations?

Maintenance and Lifespan: Is it necessary to protect against corrosion? Is it easy to clean?

Providing this information to your Grating Manufacturer will allow them to produce an accurate Grating Design and will allow for a long-term Grating Reliability.

Industrial Applications of Metal Gratings

Some of the following are examples of Metal Grating Applications:

- Walkways and access platforms

- Mezzanine and stair treads

- Drainage and trench systems

- Chemical and petrochemical processing

- Power plants, ports, and manufacturing facilities

Each application will require a specific Grating Design based on the rated loads, the environment in which the Grating will be located, and any required safety features.

Why EarthTech Engineering Works Is a Trusted Grating Manufacturer

EarthTech Engineering Works is a leading Grating Manufacturer in Gujarat. We are reliable suppliers to the largest industrial areas, such as Vadodara, Ankleshwar, Dahej, Surat, Ahmedabad, and surrounding GIDC areas, we manufacture a variety of Gratings based on our capabilities and focus on quality industrial-grade products and provide customized Grating solutions for your application.

As a trusted Grating Manufacturer in India, we provide the following supports to projects:

– Custom-made Gratings

– Multiple Load Classes and Finishing

– Industry Based Engineering Support

– Consistent Quality with Timely Delivery

Frequently Asked Questions

Q1. What are the most common types of grating?

Bar grating, expanded metal grating, perforated metal grating, and safety grating are the most commonly used in industrial applications.

Q2. Which grating is best for heavy industrial loads?

Bar grating is preferred for heavy loads due to its superior strength and rigidity.

Q3. What type of grating is suitable for chemical plants?

Safety grating or stainless steel bar grating is ideal due to slip resistance and corrosion protection.

Q4. How is bar grating different from expanded metal grating?

Bar grating offers higher load capacity, while expanded metal grating is lighter and more economical.

Q5. What factors affect grating selection?

Load requirements, environment, safety needs, installation location, and maintenance expectations.

Q6. Can industrial gratings be customized?

Yes, gratings can be customized based on size, load class, material, and surface finish.

Request Specifications or Get a Quote

Selecting the right grating starts with the right information. Share your load requirements, application area, and environmental conditions, and our team will help you choose or fabricate the most suitable solution.